Dr I

Gilchrist

Dr I

Gilchrist

PhD. MSc. BSc. C.Eng. M.I. Mech. E.

ENGINEERING

CAREER REVIEW

This text is extracted from a document prepared for the

Institution of Mechanical Engineers

Please Click on the relevant item

Biomedical Engineering Research

Anaesthesia and Lung Ventilation

Biomedical Industrial Collaboration

Postgraduate Biomedical Courses

Involvement with SEED and other Professional Organisations

Involvement with the Institution of Mechanical Engineers

Northern Ireland Graduate and Student Section

========================================================================================================

|

dates |

Qualification |

Institution |

Notes |

|

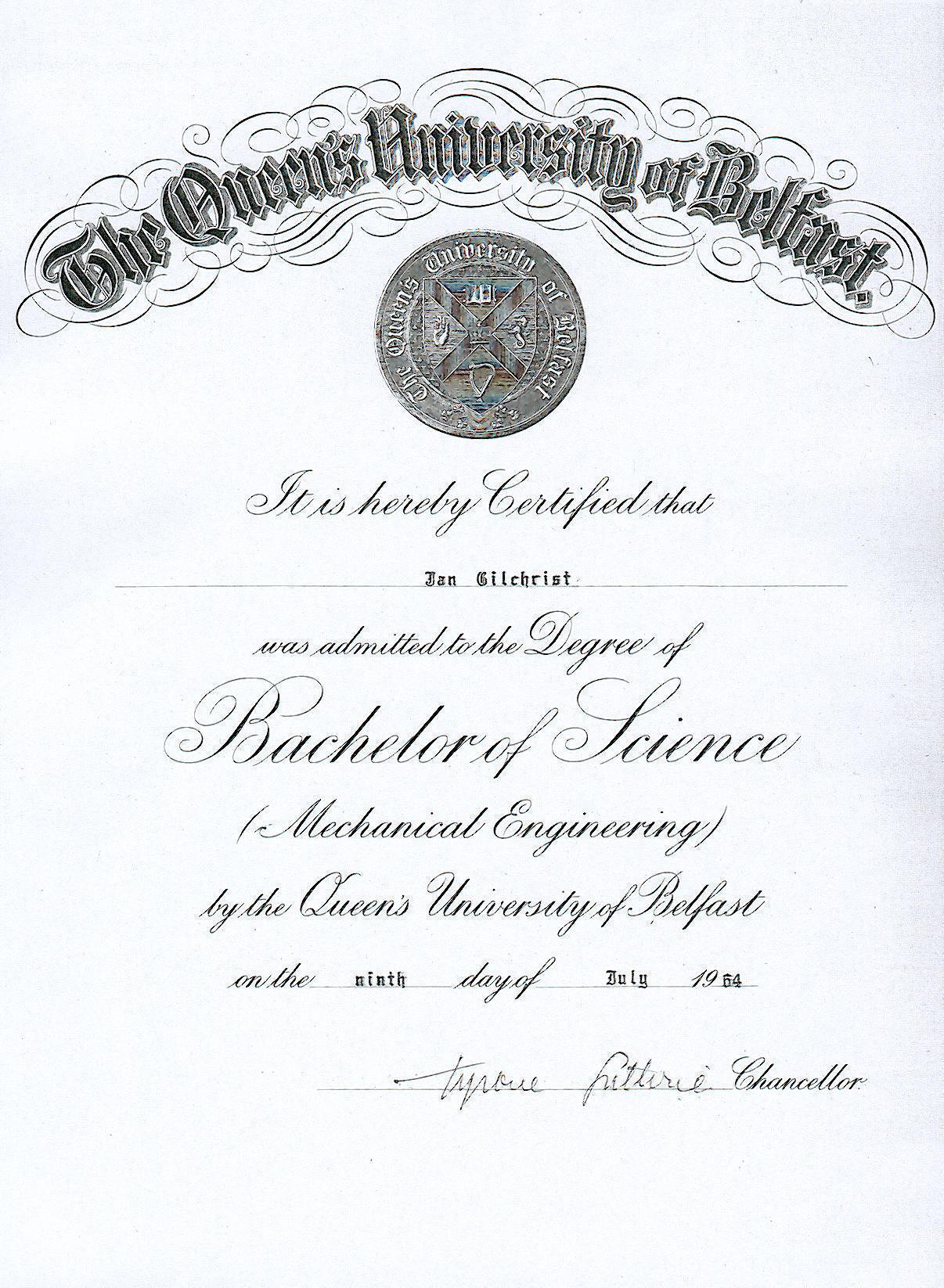

1960 to 1964 |

BSc Thin Sandwich Course Degree in Mechanical Engineering.

|

Queens University of Belfast |

Topics included: Thermodynamics, Fluid Mechanics, Solid Body Mechanics, Dynamics, Engineering Materials and Manufacturing Processes.

I also completed a thin sandwich course graduate apprenticeship with Harland and Wolff Ltd. |

|

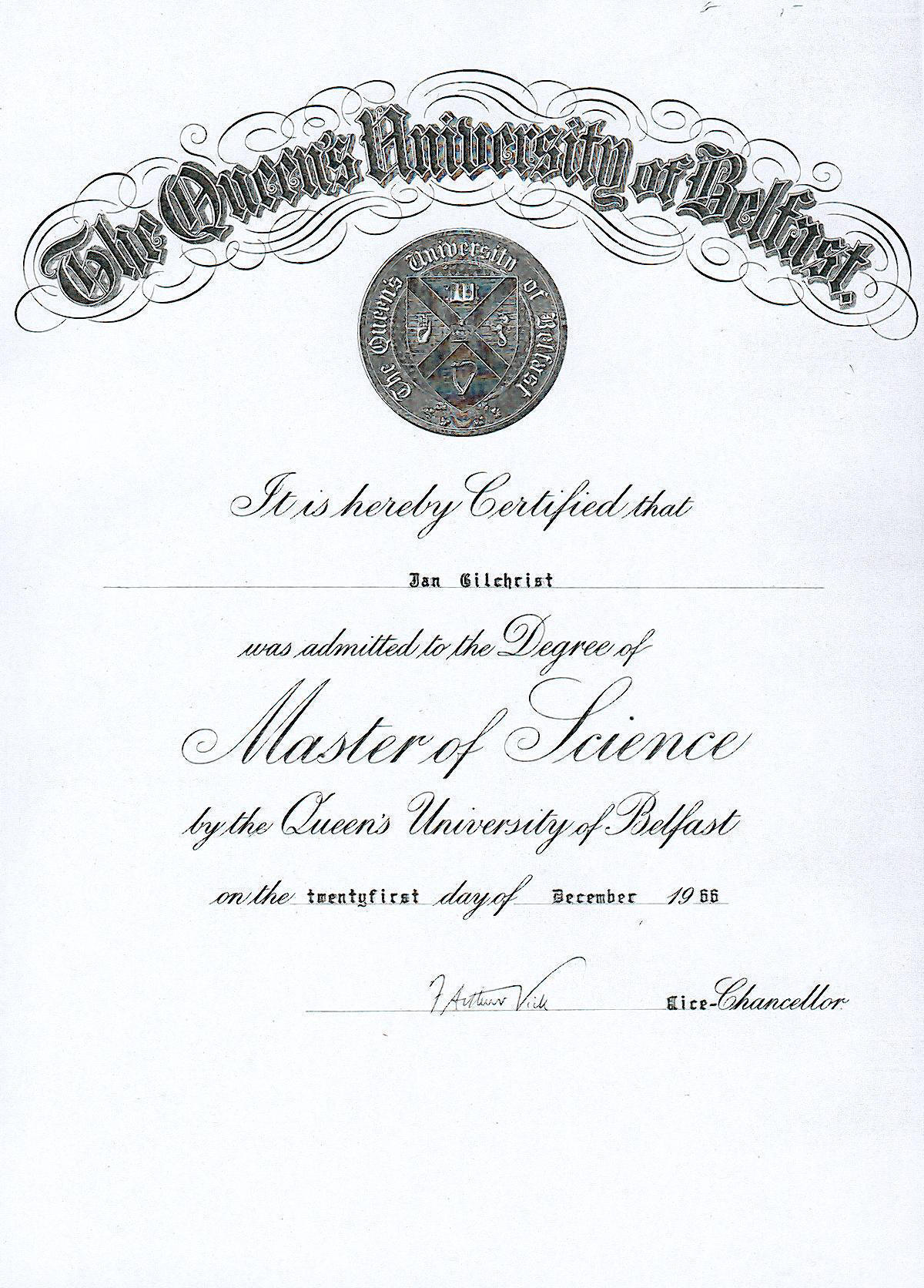

1964 to 1966 |

Research MSc in Mechanical engineering |

Queen’s University of Belfast |

The degree was awarded for research into the explosive forming of sheet metal using an underwater electrical discharge.

Metallurgical and physical aspects of sheet metal forming were investigated as well as the electrical parameters and the dynamics of the discharge |

|

1966 to 1972 |

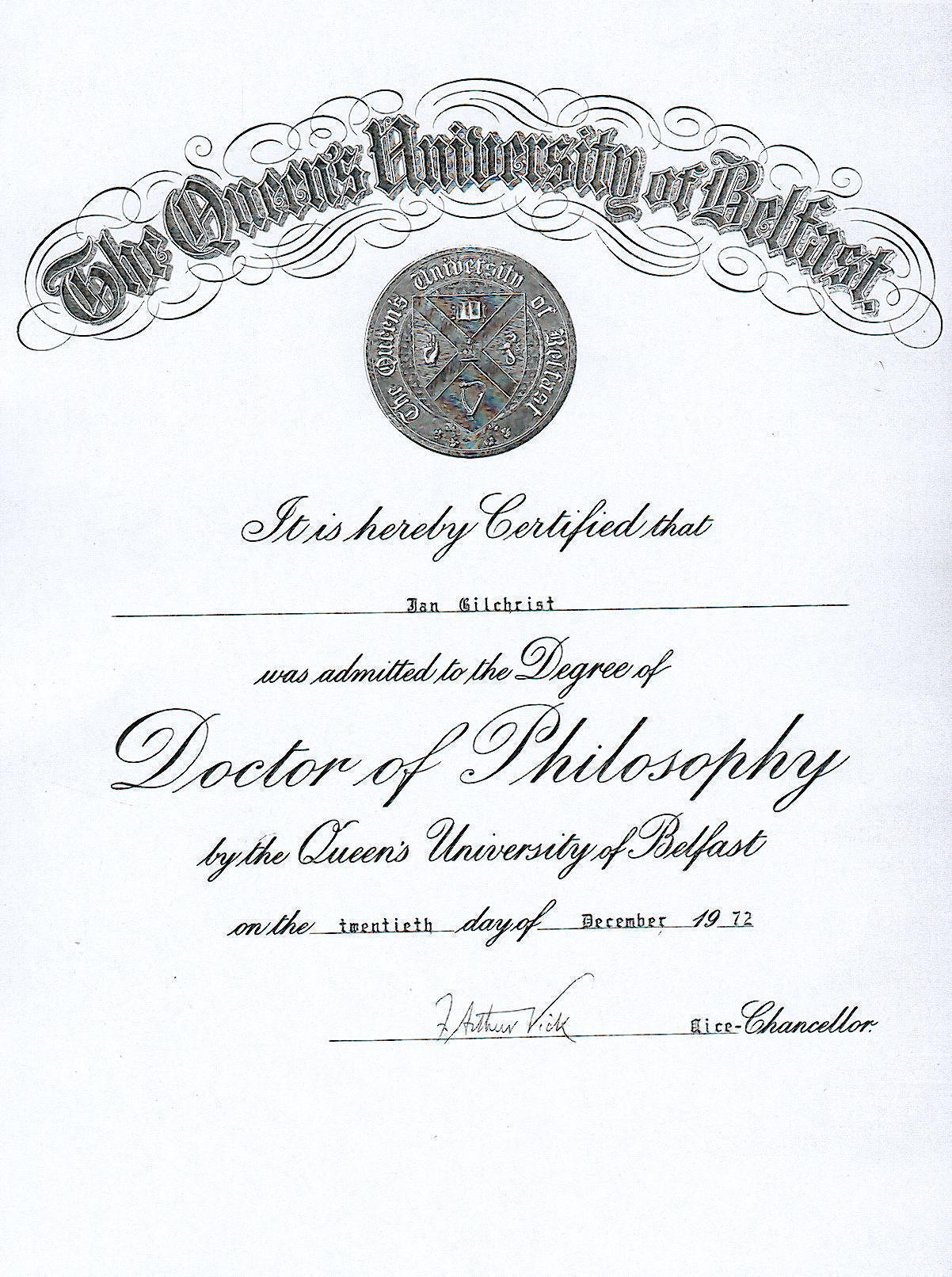

PhD in mechanical engineering

Appendix C contains copies of the degree certificates. The originals are available on request. |

Queens University of Belfast |

The degree was awarded for the design and development of equipment to conduct research into deep sea life. Animals were recovered under constant temperature and pressure from the deep sea and studied in special observational vessels on board ship. As well as designing and developing the equipment my personal research involved studies of the trapping and recovery methods as well as the requirements for pressure and temperature maintenance. This work also included research into and the design and development of new types of large diameter high pressure observation windows suitable for laboratory use. A full range of proving tests were also required. |

At a time when I personally considered seeking transfer from Graduate to Corporate Membership of the Institution I deferred doing so. I felt that I was giving more to the Institution and getting more from it through my involvement in these activities. I resigned as Chairman of the Graduate and Student Section in October 1970 when, for employment reasons, I had to leave Northern Ireland.

I have continued my membership of the Institution of Mechanical Engineers to the present time.

Until the early 1990’s every student at Brunel University was required to undertake a thin sandwich course. The satisfactory completion of the industrial training was required for a degree. The university now offers an optional thick sandwich course. The Institution of Mechanical Engineers, under its Monitored Professional Development Scheme, currently accredits the Department to oversee industrial training on its behalf. Until my retirement I was responsible for monitoring the industrial training of my tutor students and confirming that it satisfied the university requirements and those of the Institution of Mechanical Engineers.

From 1988 to 1998 I was a member of the National Executive Committee of SEED (Sharing Experience in Engineering Design). SEED was set up as an organisation promoting the development of Engineering Design Teaching at tertiary level throughout the United Kingdom. I was the SEED conference manager for the whole of this period.

During my 10 year period as the SEED Conference Manager I organised annual National and International conferences on Engineering Design Education. My role as conference manager was to organise and administer all of the intellectual content of the conferences. This included the setting of programmes, identifying topics, inviting papers and organising the presentations. It included the organisation and administration of the peer review process. I was also responsible for the preparation, editing and the publication of the proceedings.

With the support of the SEED Executive Committee my approach was to develop a continuing programme of conferences each of which had a clearly defined strategy in promoting Engineering Design Education. The conference topics included: Project Work and Industrial Links in the Teaching of Design, How industry uses and will use its future designers, Implementing the SEED approach to design education, Interdisciplinary Engineering Design, Student Assessment, Creativity in Engineering Design, Design Principles for Quality Design, Quality and Qualification, Reshaping Design Teaching, A Strategy for the Introduction of Computer Aided Learning into the Design Curriculum, Design at the Interface and Attracting and Motivating Engineering Students Through Design.

I was also responsible for the editing and publishing of the SEED Project Compendia. These compendia are intended to enhance the teaching of engineering design. For all projects the student time requirement and resource implications are listed. The distinctions between project and educational objectives are clearly defined.

In my role as a member of the SEED National Executive Committee, as Conference Manager, and as Chairman of the Project Compendia Editorial Board I believe that I have made a significant contribution to the Development of Engineering Design Teaching at National and at International level.

In terms of personal development I have gained the experience that comes from organising continuing programmes of large and small scale conferences. As well as acting in my role as SEED conference manager I have hosted and organised similar international conferences and seminars in the fields of engineering design and in biomedical engineering. These activities require me to keep up to date in each topic. Because of this I am able to take a strategic view and apply it to the furtherance of engineering and of engineering education.

I am also a member of the Society for Underwater Technology.

Areas of Responsibility

Achievements

My research interests have been principally in the fields of Sheet Metal forming, High Pressure Engineering, Deep Sea Research, Offshore Engineering, Engineering Design and Biomedical Engineering.

Much of this work has been applied research carried out in collaboration with industry and with other academic partners. I have also engaged in technology transfer and in design and development work with biomedical engineering and offshore engineering companies. Examples include the design and development of cash dispensing machinery with De La Rue Systems, the design and development of antilock braking systems with the Transport Research Laboratory and remote access equipment with Niftylift Limited. Biomedical Engineering work has been undertaken with the Royal Postgraduate Medical School, Hillingdon Hospital, and with other Teaching Hospitals. Consultancy work and other projects have also been undertaken.

A selection of four areas of my research and teaching activities is given below:

Deep Sea Research and Offshore Engineering

Recovery of Deep Sea Animals at Constant Temperature and Pressure

This programme of work re-instated the research and development work carried out during my previous employment, for which I was awarded a PhD.

In this earlier work animals were recovered under constant temperature and pressure from the deep sea and studied in special observational vessels on board ship. That work is reported in more detail elsewhere in this document. However this earlier work had shown that while many animals could be trapped at the shallower depths there was an insufficient supply at greater depths.

In 1974 I therefore proposed adapting the equipment to trap and recover animals living on the abyssal ocean floor. The programme was carried out in collaboration with Dr Alister Macdonald, a biologist from Aberdeen University. A major re-design of the original equipment had to be undertaken but this proved successful and it led to a rolling programme of research and development supported by the Natural Environment Research Council which lasted for the next 14 years. The system was designed to operate at all ocean depths, including those of the deep trenches.

The equipment has also been exhibited twice by invitation in the Royal Society and once in the Royal Institution, as an exemplar of British university research. This equipment, together with a selection of failed high pressure window test samples taken from the window research programme has since been acquired by the Science Museum and it now forms part of the National Collection.

None of this work could be delegated to my research students because of the need to meet timescales for research cruses etc. Therefore the whole of the equipment development programme, including the detailed design work, the development of new trapping and recovery methods and the logistics of the operation was my sole responsibility.

Other Marine Research

I have also undertaken consultancy and research work for the offshore oil industry. This included the design and development of new types of sea bed sampling devices. These assess the suitability of the sea bed for the foundations of offshore structures. Work has also been carried out on remotely controlled submersible design. This has included initial work on the hull design for the NERC Autosub, which is used for deep sea exploration. The particular challenge to be met was that of achieving a hull design which had adequate strength while minimising changes in buoyancy encountered with increasing depth.

My Biomedical Engineering Research has been carried out in the areas of Audiology, Anaesthesia, Lung Ventilation, Drug Delivery and Hospital Equipment Design. Much of the work on Anaesthesia and Lung Ventilation has been carried out in collaboration with the Department of Anaesthetics of the Royal Postgraduate Medical School at Hammersmith Hospital. The Audiology work has principally been undertaken with Hillingdon Hospital. However other major London teaching hospitals have been involved.

My work has concentrated on the development of neonatal screening processes and speech recognition in noise. This included continued support for the Auditory Response Cradle which is used for the mass screening of the hearing of newborn infants. Research has also been undertaken into the development of hearing mechanisms in premature children. Other work has investigated the speech recognition in noise capabilities of schoolchildren. Much of this work aims to apply engineering and mathematical techniques to the understanding of physiological processes.

Anaesthesia and Lung Ventilation

My work on anaesthesia and lung ventilation has explored new methods and techniques including those of jet ventilation and high frequency ventilation. Normal methods of ventilation tend to move the lungs in synchronicity with the expected breathing activity. However high frequency and jet ventilation rely more on the diffusion patterns of gases injected into the lung. The method may be used to limit the lung movement required and this is particularly important in the treatment of seriously injured patients. Both the physiological and mechanical aspects of lung ventilation have been investigated. Other work has involved research into associated topics such as vapourisers, drug infusion devices and anaesthetic equipment.

Industrial Collaboration and Lung Ventilator Design

A collaboration of particular interest was a Teaching Company Programme which I set up jointly between Brunel University, the Royal Postgraduate Medical School and Blease Medical Equipment Limited. I was the originator and principal grant holder for this programme. Additional funding was provided by the scheme for the appointment of a clinical registrar.

Blease Medical Equipment Limited was a well respected Anaesthetic Equipment and Lung Ventilator manufacturer. It had survived to that time by making incremental changes to the product range it had introduced many years previously. However the company could no longer survive on this basis. The aim of the Teaching Company Programme was to turn the company round by establishing a stronger research and development base.

The objectives of the programme stated that a new range of lung ventilators were to be developed. Four Teaching Company Associates, with backgrounds in mechanical and electronic engineering and engineering product design took part in the development of the artificial ventilator equipment. Much of the initial work for the first ventilator concentrated on analyzing component reliability and performance. Considerable care was taken to provide a reliable and fail-safe system and special attention was paid to the user interface for doctors, nurses and patients.

The overall aim of the Teaching Company Programme was to design, develop and produce a range of cost effective lung ventilators that would provide the company with the expertise and experience to develop new and advanced products which would ensure the company could succeed in a rapidly evolving market. Subsequent to the Teaching Company Programme, Blease has become a leading supplier of OEM products and components to the worldwide anaesthesia industry. Its products are sold internationally in anaesthesia, critical care and emergency care areas. The company markets extensively both to the NHS and private hospitals in the UK and overseas. Blease Medical Equipment continued to operate as an independent company until 2005.

Much of the turnaround can be attributed to the teaching company programme. The research and development team consisted essentially of the four teaching company associates and one company electronic engineer. Teaching Company Associates are normally appointed for a maximum of two years however, with company support, all of the associates each remained in this post for four years. The first ventilator which was developed in this programme was exhibited in the Science and Engineering Research Council and the Design Council Exhibition “From Academic Research to Engineering Design” held from the 24th May to the 6th July 1989 in the Innovation Centre at the Design Centre 28 Haymarket London SW1. The ventilator and the Teaching Company Programme was also the subject of a promotional video made for the Teaching Company Scheme. In addition the Design Council short listed this ventilator against other commercial products as a potential winner of a National Design Council British Design Award.

My principal contribution in this work was to the organisation and management of the programme. I was also responsible for the supervision of the associates; the four teaching company associates were employees of Brunel University and were directly responsible to me, however the day to day line management lay principally within the company. There was considerable academic input from Brunel University and from the Royal Postgraduate Medical School, myself included. The programme was very successful but management difficulties can occur when people from outside are grafted into an existing company organisation, and this is where some of the challenges were found.

Areas of Responsibility in Research

I have been responsible for developing introducing and directing all of the undergraduate and postgraduate courses in Biomedical Engineering and Engineering Design which have been offered by the Department. In addition to the courses which are described in more detail in this document I was responsible for the planning, introduction and running of an undergraduate course on Mechanical Engineering with Biomedical Applications.

I was also responsible for the planning, introduction and directing of the first (pre SARTOR) MEng Degree programme offered by the University. In addition to this I was also responsible, jointly with a colleague from the Department of Design, for the planning, introduction and directing of the current joint MEng degree programme in Mechanical Engineering and Design, which is accredited by the IED.

Teaching of Solid Body Mechanics

From the time I was first employed by Brunel University until the full implementation of the Engineering Design courses my principal teaching role was that of lecturing Solid Body Mechanics. I taught both Statics and Dynamics at all levels of the course and I developed of new modules and teaching techniques which provided an integrated approach.

From the time of its introduction I have had personal responsibility for the implementation and development of design teaching within the department. As the Module Leader I have personally developed and introduced all of the design teaching modules offered at all levels on the course, apart from the module for Level 2, which I currently teach. I introduced and, until retirement I was the co-ordinator for the M Eng Level 5 group design projects. I was responsible for developing a design teaching centre with a staffed and equipped design office for staff and student use. As Chairman of the Applications Panel I have had oversight of all of the engineering design, materials and manufacturing teaching carried out within Mechanical Engineering.

Until the 1990's every undergraduate student at Brunel University undertook a thin sandwich course. Because of this the engineering design courses could be developed in a way which fully integrated the industrial and academic activity. The first year course concentrated on developing the understanding of the principles of the design process. The second year course focussed on component design and was designed to take advantage of the industrial experience which the returning students had gained. This was modelled on the design office of a small consultancy firm where students had to respond to requests from the clients who were represented by the academic staff. In the third year more broadly based project work was carried out, which concentrated on engineering system design and also drew on the industrial experience that the students had received. In the fourth and final year of the four year course students were able to take an "Applications Theme" which delivered modules with a specialised design focus

In order to round off the student experience I considered it appropriate to introduce a concluding final year module which requires each student to take an overview of the role and impact of engineering design. This module requires students to prepare and present individual reports on the implementation of these procedures in an industrial context. Each student acts individually in the capacity of a consultant making recommendations to a general engineering company management about the implementation of new engineering design and manufacturing procedures. A company profile, outline strategy and company accounts are provided. This module enforces a change in outlook from student learner to that of a design assessor. It aims to develop the perceptions and responsibilities required by a practising engineer. It provides a rounding off experience which consolidates and completes the understanding of engineering design generated through the undergraduate degree.

The loss of the industrial training associated with the disappearance of the thin sandwich course has meant that there has had to be a downwards revision of the expectations associated with engineering design teaching. Many students can now proceed through the undergraduate course without gaining any industrial experience at all. Nevertheless it was not considered necessary to change the principles involved in teaching the design courses although the strategy, learning outcomes and the syllabuses had to be revised to meet the new expectations. The B Eng students, who currently complete the course in the third year (at level 3) are required to undertake a group project on engineering systems design. The M Eng students are required to replace this with the M Eng Group Design Project which is undertaken (at level 5), in the fourth and final year of their course.

Postgraduate Courses in Engineering and in Biomedical Engineering

At different times I have been responsible for the design, development and introduction of both undergraduate and postgraduate degree courses in Biomedical Engineering. I was also responsible for planning and introducing the first M Eng degree course offered by the Faculty of Technology at Brunel University.

I was personally responsible for proposing, planning and introducing the current MSc in Biomedical Engineering and the MSc in Biomedical Engineering and Innovation courses which are described below. I was Course Director for both of the courses until my retirement from full time employment at Brunel University at the end of September 2006. I continue to teach part time on the course.

When I was planning these courses I took great care was taken to match the academic objectives to the clinical and industrial need. This had a significant impact on the structure adopted. While engineering in medicine is playing an increasing role in diagnosis, treatment and therapy, much of the engineering input has been fragmented in nature. Many small companies are designing innovative products that because of skill and resource restrictions have been taken into production through licensing abroad.

While the United Kingdom medical devices industry is well established in electro-medical, orthopaedic, anaesthetic and respiratory equipment and in the dressings and disposable sectors, the industry lacks the cohesion and organisation to allow it to compete effectively on a worldwide basis. In order to maintain its present position it needs to develop and maintain its expertise in these areas. For this well trained graduates are needed who can develop and manage effective and appropriate projects in a company, academic or clinical environment, and develop the co-operative and cross disciplinary links required for working in biomedical development and research.

Both of the Master’s courses are developed as partnership programmes between industry, academia, medical and healthcare sectors. Extensive consultation with the three sectors has taken place and each course is designed to meet the current and future medical industrial and research needs.

Each taught module is presented in a short course format. Modules were also delivered and assessed within a four week period. The maximum period of registration for both courses is four years. Subject to certain constraints, modules may be taken at any time during the period a student is registered for the course. This means that modules may also be taken independently as part of a Continuing Professional Development Programme of studies. The flexibility this offers is intended to be attractive to firms who wish to offer the programmes to staff in an in service training capacity. It also takes account of the particular concerns that smaller organisations have about releasing essential staff to take part in an academic course

The two courses each have a different focus. The MSc in Biomedical Engineering Course provides a programme of study for biomedical engineers who wish to advance and update their knowledge of biomedical engineering. It has a research perspective and it can be completed in a minimum period of one academic year. It is aimed at more experienced Biomedical Engineers and those students (including overseas students) for whom the industrial training element would not be appropriate.

The first student intake on the MSc in Biomedical Engineering course took place in October 2005. The course has been well received. The short course format proved popular with students however some of the weaker students had difficulty in adapting to the demands that this creates. Some of the academic staff felt challenged by the timescales required to deliver and assess a module within a period of four weeks. However if Universities and other Institutions are to meet the increasing demand for Continuing Professional Development Courses, adaptations of this type are required. The format adopted by the Biomedical Engineering modules has been strongly supported by senior management in the University.

Additional academic input is also needed to promote and to support the Industrial Training Requirements of the MSc in Biomedical Engineering and Innovation Course. As a consequence of my retirement from Brunel University I no longer have control over these matters. Therefore the future development of the MSc in Biomedical Engineering and Innovation Course will depend on the wishes of the current academic staff.

From October 1966 to September 1970 I was employed by the Mechanical Engineering Department of the Queen’s University of Belfast to undertake research into, and to design and develop equipment to recover mid water deep sea animals under constant temperature and pressure for biological study.

Later, in 1974, while lecturing at Brunel University I revived this research by establishing a research programme which concentrated on the recovery and study under constant temperature of Benthic (bottom living) deep sea animals instead. The work with benthic animals has been discussed elsewhere in this document.

The description given here concerns the mid water trapping programme. As well as designing and developing the equipment my research work involved studies of the trapping and recovery methods together with the requirements for pressure and temperature maintenance. More details are given below.

Little was known about the population density of deep sea life. As well as conducting theoretical investigations it was also necessary to organise experimental research programmes in the deep sea to assess the feasibility of the approaches considered. The requirement to maintain pressure and temperature within the specified limits meant that novel approaches were also required. Laboratory test facilities were constructed.

This work also included research into and the design and development of new types of large diameter high pressure observation windows suitable for laboratory use. Piccard and others had used conical PMMA windows for deep sea submersibles and preliminary studies showed that this type of window might be feasible in this application. However the duty requirements were far in excess of those required for submersible operation.

Instead of being taken to pressure slowly and infrequently in a submersible these windows had to be capable of withstanding pressures 1.4 times greater than that at the greatest known ocean depth. They were also to be taken to these pressures both rapidly and frequently in the ship’s laboratory. Safety is also paramount since an observer is likely to be looking through the window all times. A full range of proving tests were required and a substantial research programme was also carried out into window behaviour. This included cyclic and fatigue tests as well as static strength tests, under different loading and environmental conditions. As well as establishing the appropriate parameters for use in the investigation, the research programme also identified the nature of window behaviour and the requirements for the optimisation of window design this and more general applications. As far as the author is aware this research has never been superseded. Samples of tested windows together with the deep sea exploration equipment now form part of the Science Museum National Collection.

During this period I was seconded to the Mechanical Engineering Department of the Queen’s University of Belfast to conduct research into Sheet Metal Forming The research involved an examination of the formability of sheet metal using the explosion created by an underwater electrical discharge.

The name often used to describe the process is that of Electro Hydraulic Forming. This work was part of a research programme into Explosive Forming and Explosive Welding carried out in the Department of Mechanical Engineering of the Queen's University of Belfast. While explosive forming is very suitable for forming individual components it is not suitable for use in regular production.

In order to eliminate the need to handle explosives an electric discharge was employed. A series of capacitors were charged to a voltage of 40,000 volts and short circuited through an underwater spark gap. The resulting explosion was then used to form the sheet metal. The technique lends itself to the forming of large number of smaller components, each of which has a similar but differing shape. An appropriate application is the forming of stainless steel dentures and this was the initial focus of the study.

A review of the literature and initial experiments, carried out both with and without an initiating wire bridging the spark gap, made it clear that there was not a clear understanding of the parameters controlling the electrical discharge. This research attempted to resolve these issues. It provided reasons for the variability encountered and it showed how more reliable results may be obtained. Metallurgical parameters were also investigated and stainless steel dentures were successfully formed.

Overall the investigation established the criteria involved in electro-hydraulic forming. It showed how efficiency may be improved and how more reliable operation may be obtained. In addition it demonstrated the feasibility of the method and provided some guidelines to be applied to the forming of sheet metal shapes.

I was personally responsible for the commissioning of the equipment and for conducting the research. A major challenge I faced was to find ways of explaining the lack of correlation of the results obtained by previous investigators. Because of this I carried out substantial research into the electrical characteristics of high voltage underwater discharges, in addition to the sheet metal forming investigation. This identified the reasons for the inconsistencies encountered.

From September 1960 to September 1964 I was sponsored by Harland and Wolff Ltd to undertake a Mechanical Engineering Degree on a Thin Sandwich Course at the Queen’s University of Belfast. During this period I also completed a graduate apprenticeship. Appendix B contains a schedule of this training experience. I also hold a letter from the Institution of Mechanical Engineers which states that I have satisfied the Academic and the Industrial Training Requirements applicable for Corporate Membership at the time.

Appendix B contains a copy of the schedule.

6 Voluntary Non Engineering Activities

Outside my engineering activities I have made a substantial contribution to social and reconciliation work, including the creation and management of organisations which are engaged in such activities. In November 1969 I produced a report that identified programmes for reconciliation work in Northern Ireland. This was taken up by local government and it had a significant impact on its policy. I was also responsible for setting up community initiatives in the province. Subsequently in England I was responsible for setting up and overseeing an organisation which co-ordinated support throughout mainland Britain for reconciliation work in Northern Ireland. The organisation employed paid staff and has it made substantial financial and social contributions to reconciliation activities. In this organisation I have personal experience as Chairman and Vice Chairman, and I have been an office bearer for the whole of its existence which lasted for 21 years. Currently I am working with a number of organisations in London and elsewhere to develop a programme which aims to draw on the experiences of reconciliation work in different areas throughout the world so that we may be able to apply the lessons learned to the current United Kingdom situation. Further information is on the Social and Reconciliation Work pages of the website www.crestcons.org.

Responses to these statements were requested by the Institution of Mechanical Engineers.

. :

The equipment I developed during my work on the recovery and study of deep sea life was exhibited by invitation twice in the Royal Society and once in the Royal Institution as an exemplar of British University Research. This equipment now forms part of the Science Museum National Collection

The lung ventilator developed during the Teaching Company Programme, for which I was the initiator and principal grant holder, between Blease Medical, The Royal Postgraduate Medical School, and Brunel University, was exhibited by the Design Council in London in an exhibition with the theme of “From Academic Research to Engineering Design”.

The ventilator was also short listed by the Design Council for a National Design Award

The line of employment reporting is shown in bold. There are different lines of reporting for postgraduate teaching, undergraduate teaching and for research.

![]() 9

Continuing professional development (CPD)

9

Continuing professional development (CPD)

Details of my approach to previous activities are given in section 7.16

A list of publications is given in Appendix A

I intend to continue my present part time teaching roles in Engineering Design and Biomedical Engineering at Brunel University. I also aim to keep my interests in Biomedical Engineering research by maintaining my industrial and clinical contacts and by the supervision of MSc dissertations and other projects in biomedical engineering.

I will consider consultancy work in engineering design or in course development as appropriate. I intend to use my experience in engineering and engineering design to promote and support the engineering profession and to advocate new courses and approaches in engineering education which integrate the education and training experiences gained during the formation of young engineers.

Throughout my career I have demonstrated my commitment to the engineering profession. This provides me with future opportunities to develop my commitment to engineering through the use of my experience for addressing engineering concerns. I am also more than happy to encourage interest in engineering and to promote enthusiasm in students and young engineers.

I do not believe that engineering education can be effective without a proper integration of the academic and industrial elements and I have tried to promote this throughout my career. There are still major hurdles to be overcome. The use of peer review processes to promote research in Universities is focusing the interests of staff into increasingly narrow areas. It also leads to the recruitment of staff with limited experience of the breadth that engineering requires. Academic timescales do not match industrial needs. My recent work on the development of new biomedical engineering and engineering design programmes has been an attempt to address these professional and cultural concerns.

Publication List

I Gilchrist with B Crossland

"The Forming of Sheet Metal using and Underwater Electrical Discharge"

Proceedings of the Conference on Electrical Methods of Machining and Forming

Conference Publication No. 38, pages 92-113

Institution of Electrical Engineers

5-7 December 1967

I Gilchrist with A G Macdonald

"Life in the Ocean Depths"

Proceedings of the Oceanology International Conference 1969

Technical Sessions, Day 1, page 27

Brighton

February 1969

I Gilchrist with A G Macdonald

Marine Research: supplement to Research

Vol. 2, part 4, pages 14-20

June 1969

I Gilchrist with A G MacdonaldPRIVATE

"Recovery of Sea Water at Constant Pressure"

Nature, Vol. 222, No. 5188, pages 71-72

1969

I Gilchrist with R Lincoln

"An Observational Pressure Vessel for Studying the Behaviour of Planktonic Animals"

Marine Biology, Vol. 6 No. 1

May 1970

I Gilchrist with A G Macdonald and J M Teal

"Some Observations on the Tolerance of Oceanic Plankton to High Hydrostatic Pressure"

Journal of the Marine Biological Association of the United Kingdom

Vol. 52 pages 213-223

1972

I Gilchrist with A G Macdonald

"An Apparatus for the Recovery and Study of Deep Sea Plankton at Constant Temperature and Pressure"

Chapter 5, pages 294-412 in

"Baro-biology and the Experimental Biology of the Deep Sea"

(ed. R W Brauer)

University of North Carolina Press

1972

I Gilchrist with A G Macdonald

"Further Studies on the Pressure Tolerance of Deep Sea Crustacea with Observations using a new High Pressure Trap

Marine Biology Vol. 45, pages 9-21

1978

I Gilchrist with A G Macdonald

"The Pressure Tolerance of Deep Amphipods recovered without Loss of Pressure from a Depth of 1300m"

Proc. Society of Experimental Biology

University of Sussex Meeting

Brighton

January 1978

I Gilchrist with A G Macdonald

"The Recovery of Animals Under Conditions of Constant Temperature and Pressure from the Deep Sea"

Proc. Society of Experimental Biology

Aberdeen Meeting

July 1980

I Gilchrist with A G Macdonald

"Effects of Hydraulic Decompression and Compression on Deep Sea Amphipods"

Journal of Comparative Biochemistry and Physiology

Vol. 67A, pages 149-153

1980

I Gilchrist with A G Macdonald

"Hydraulic Decompression Neurological Syndrome in Deep Sea Animals"

J. Physiology

Vol. 305, pages 35-36

1980

I Gilchrist with A G Macdonald, S A Wilcock and K T Wann

Chapter in "Animals and Environmental Fitness"

(ed. R Gillies)

Pergamon Press

Oxford

1980

I Gilchrist with A G Macdonald

"Pressure Tolerance of Deep Sea Amphipods collected at their Ambient High Pressure"

Comp. Biochem. Physiol.

Vol. 71A, pages 349-352

1982

I Gilchrist with A G Macdonald

"Techniques for Experiments with Deep Sea Animals" in "Experimental Biology at Sea"

(ed. A G Macdonald and I G Priede)

Academic Press, London

April 1983

I Gilchrist with A G Macdonald and I G Priede

"Divers Submersibles and Unmanned Vehicles" in "Experimental Biology at Sea"

(ed. A G Macdonald and I G Priede)

Academic Press, London

April 1983

I Gilchrist with A J Reynolds and J R Paige

"Method and Apparatus for Propelling Projectiles"

UK Patent No. GB2058182 B

Published 23 November 1983

I Gilchrist with M K Chakrabarti and L H Loh

"High Frequency Ventilation and Gas Diffusion"

Acta Anaesthiol Scand

Vol. 28, pages 544-548

1984

I Gilchrist with A Forbes, T Green, A A Harper, A G Macdonald, V McDiarmid, J P Pennec, N Tetteh-Lartney and C Wardle

"Spontaneous activity in isolated hearts of deep sea fish from 900 and 4000 metre depths, 90 and 400 atmospheres pressure: Preliminary results of Challenger Cruise 68/85"

Proc. Physiological Soc. Vol. 377, pages 115

1986

I Gilchrist with A Forbes, T Green, A A Harper, A G Macdonald, V McDiarmid, J P Pennec, N Tetteh-Lartney and C Wardle

"The tolerance of shallow and deep sea fish to hydrostatic pressure: Final preliminary report of the Challenger Cruise 68/85"

Proc. Physiological Soc. Vol. 384, pages 37

1987

I Gilchrist with A G Macdonald and C S Wardle

"Effects of hydrostatic pressure on the motor activity of fish from shallow water and 900 metre depths: Some results of the Challenger Cruise 68/85"

Comp. Biochem. Physiol. Vol. 88A, No. 3, pages 543-547

1987

"Design Projects"

Proceedings of the 10th Annual SEED Conference

Brunel University,

SEED Ltd, Hatfield, ISBN 0 948673 17 6

June 1988

"Initiatives in UK Engineering Design through Industrial Involvement"

Proc. IMechE: Engineering Design Volii, Iced 89 Conference, Harrogate

Pages 10071025,

August 1989

I Gilchrist (Ed)

"How Industry uses Designers"

Proceedings of the 11th Annual SEED Conference

Bath University, June 1989

SEED Ltd, Hatfield, ISBN 0 948673 20 6

June 1989

I Gilchrist (Ed)

"Interdisciplinary Engineering Design"

Proceedings of the 12th Annual SEED Conference

Hatfield Polytechnic, June 1990

SEED Ltd, Hatfield, ISBN 0 948673 23 0

June 1990

I Gilchrist (Ed)

"SEED Project Compendium Volume 2"

SEED Ltd, Hatfield,

June 1990

I Gilchrist (Ed)

"SEED Project Compendium Volume 3"

SEED Ltd, Hatfield, ISBN 0 948673 24 9

June 1991

I Gilchrist (Ed)

"Student Assessment"

Proceedings of the 13th Annual Design Conference

UMIST,

SEED Ltd, Hatfield,

ISBN 0 948673 29 X.

June 1991

I Gilchrist

"A Self Learning Course Module in Design."

Proceedings of the 13th Annual SEED Conference

SEED Ltd, Hatfield, ISBN 0 948673 29 X

June 1991

I Gilchrist, J G Whitwam and Y Woods

"Design of a new Lung Ventilator”

Technology Transfer and Implementation Conference, Queen Elizabeth Conference Centre, London

July 1992

I Gilchrist, J G Whitwam, and Y Woods

"A Case Study in Lung Ventilator Design and Development in the United Kingdom"

Workshop Design Construction WDK 22, Vol 1, pages 111-118

Ed V. Hubka, Heurista, Zurich ISBN 385 693 0272

August 1993

I Gilchrist, P H Hamilton, and D G Smith

"Transcending Disciplines by Design - A Proven Approach"

Workshop Design Construction WDK 22, Vol 1, pages 1756-1763

Ed. V. Hubka, Heurista, Zurich ISBN 385 693 0272

August 1993

I Gilchrist (Ed)

"Creativity in Engineering Design"

Proc. of the 14th Annual Seed Conference

Cambridge University,

ISBN 0 948673 34 6,

SEED Loughborough

June 1992

I Gilchrist (Ed)

"Design Principles for Quality Design"

Proceedings of the 15th Annual SEED Conference

University of Northumbria,

ISBN 0 948673 38 9

SEED, Loughborough

September 1993

I Gilchrist (Ed)

"Quality and Qualification"

Proceedings of the 16th Annual SEED Conference

Portsmouth University,

SEED, Loughborough

ISBN 0 948673 39 7

September 1994

I Gilchrist with C Dowlen and K S Hurst

"Design the Way Forward"

Working Conference on Increasing Student Participation in Engineering Education, Sheffield Hallam University

12-14 September 1994

I Gilchrist with C M C Dowlen and K S Hurst

"Creativity in Engineering Design; Can it be taught?"

Workshop Design Konstruction WDK 23, Vol. 1, pages 291-296

Ed. V Hubka, Heurista, Zurich, ISBN 385 693 0280

August 1995

"Partnership for Quality in the Formation of Engineering Designers"

Workshop Design Konstruction WDK 23, Vol. 1, pages 324-329

Ed. V Hubka, Heurista, Zurich, ISBN 385 693 0280

August 1995

I Gilchrist (Ed)

"Reshaping Design Teaching"

Proceedings of the 17th Annual SEED Conference

Lancaster University,

SEED, Loughborough

ISBN 0 948673 40 0

September 1995

I Gilchrist (Ed)

"Computer Aided Design Education"

Proceedings of the 18th Annual SEED Conference

Bristol University,

SEED, Loughborough

ISBN 0 948673 44 3

June 1996

I Gilchrist (Ed)

“Attracting and Motivating Engineering Students Through Design

Proceedings of the 19th Annual SEED Conference

University of Hull

SEED, Loughborough

June 1997

ISBN 0 948673 49 4

June 1997

I Gilchrist, with McMahon, C.A.

"Computer Aided Learning in Design Education"

Proc ICED'97, Workshop Design Konstruction WDK 24, Vol. 3, pages 457-460 Ed. V Hubka, Heurista, Zurich, ISBN 951-722-788-4

August 1997

I Gilchrist (Ed)

“Design at the Interface”

Proceedings of the 20th Annual SEED Conference

Imperial College,

SEED, Loughborough

ISBN 0 948673 51 6

June 1998

Industrial Training Experience

From September 1960 to September 1964 I was sponsored by Harland and Wolff Ltd to undertake a Mechanical Engineering Degree on a Thin Sandwich Course at the Queen’s University of Belfast.

During this period I also completed a graduate apprenticeship with Harland and Wolff Ltd. A schedule of this training experience is given below. I hold a letter from the Institution of Mechanical Engineers which states that the training satisfies the Academic and the Industrial Training Requirements applicable for Corporate Membership of the Institution.

|

Experience and Location

|

Date Started

|

Date Ended

|

Activity

|

|

Apprentice Training Centre |

26 Sep 1960 |

3 Oct 1960 |

Induction

|

|

1st Year Academic Studies |

3 Oct 1960 |

10 Apr 1961 |

First Year of a BSc Thin Sandwich Course |

|

Apprentice Training Centre |

10 Apr 1961 |

31 Jul 1961 |

Engineering Skills including fitting, turning, machining, welding. |

|

Diesel Erection Shop

|

31 Jul 1961 |

4 Sep 1961 |

Fitting Assembly and Testing

|

|

Pattern Shop

|

4 Sep 1961 |

2 Oct 1961 |

Foundry experience and pattern making

|

|

2nd Year Academic Studies |

2 Oct 1961 |

3 Apr 1962 |

Second Year of a BSc Thin Sandwich Course |

|

Heavy Machine Shop

|

3 Apr 1962 |

7 May 1962 |

Machining |

|

Heavy Turning Shop

|

7 May 1962 |

11 Jun 1962 |

Turning |

|

Turbine Erection Shop

|

11 Jun 1962 |

30 Jul 1962 |

Fitting Assembly and Testing

|

|

Outside Engineering Works |

30 Jul 1972 |

8 Oct 1962 |

Shipboard Engine Assembly and Commissioning |

|

3rd year Academic Studies |

8 Oct 1962 |

6 Jun 1963 |

Third Year of a BSc Thin Sandwich Course |

|

Diesel Erection Shop

|

6 Jun 1963 |

30 Jun 1963 |

Management and Inspection |

|

Cooper Bessemer of Canada Ltd |

30 Jun 1963 |

1 Sep 1963 |

General Shop Floor Experience including fitting, erection, inspection and test |

|

Cooper Bessemer Inc Ohio |

1 Sep 1963 |

15 Sep 1963 |

Management, business admin and sales |

|

Cooper Bessemer of Canada Ltd |

15 Sep 1963 |

27 Sep 1963 |

General Engineering Experience including fitting and administration |

|

4th Year Academic Studies |

8 Oct 1963 |

4 Jun 1964 |

Fourth Year of a BSc Thin Sandwich Course |

|

Diesel Drawing Office |

4 Jun 1964 |

10 Aug 1964 |

Diesel Engine Design Projects |

|

Turbine Drawing Office |

10 Aug 1964 |

13 Oct 1964 |

Steam Turbine Design projects |

Copies of Degree Certificates

The originals are available on request.